Coaters/developers

var Eviry=Eviry||{};Eviry.Player||(Eviry.Player={});Eviry.Player.embedkey="EK1koSrsUy_-zCH5ksg5gz-HyjjRT5fmUp9N9OLqqQtKtqiXlxMnW4to_yPHnaM4wy-FHJ0plawEz2sRTdSUVkgQPTd1Z8o9NPjUN-cS17eU6w.";Fully automated resist, polyimide, dopant coating and baking with C to C

Compact housing built to suit wafer size

Processes various sized wafers without the need for a change of set up

Successful track record with low viscosity and high viscosity

Conveyance system handles curvature of up to 200μm

Vast range of options enables COO reduction and customization

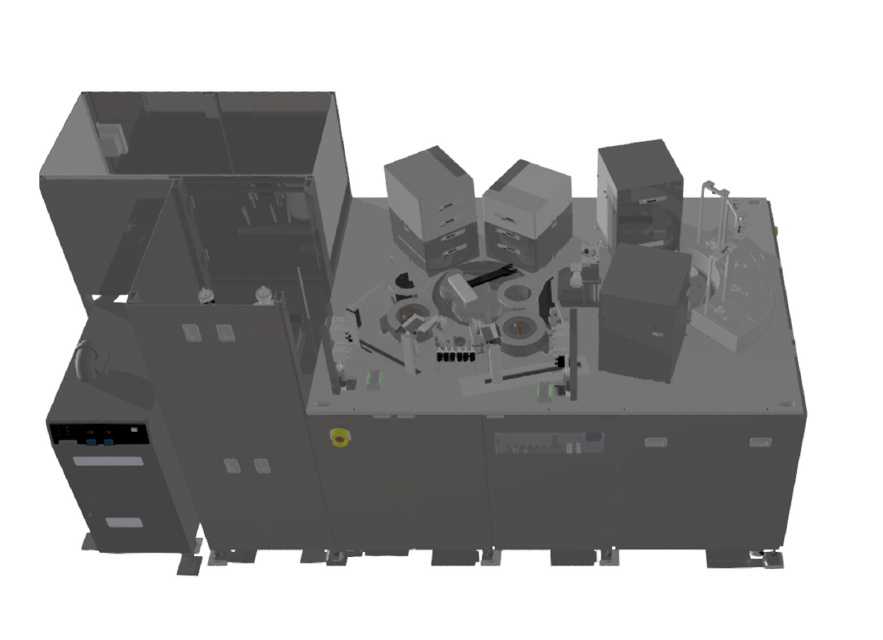

Coaters/developers01High spec models

Type: High spec

Amount processed: 1,000/day

Equipment size: Large

Robots: 2 or self-propelling

- Capable of processing over 1,000 wafers per day

High spec model equipped with all optional parts -

Equipped with two double hand wafer conveyer robots.

Unlike with conventional index/process two-robot machinery, we’ve taken into account users’ process flow to allow for customization of process unit and robot positioning and space saving, enabling highly efficient conveyance.Up to seven stages of process units may be installed, and the multistage type baking unit can be expanded to up to five stages.

In order to maximize processing capacity, software tuning taking into account process time is conducted to allow for a daily processing output of over 1,000 wafers.

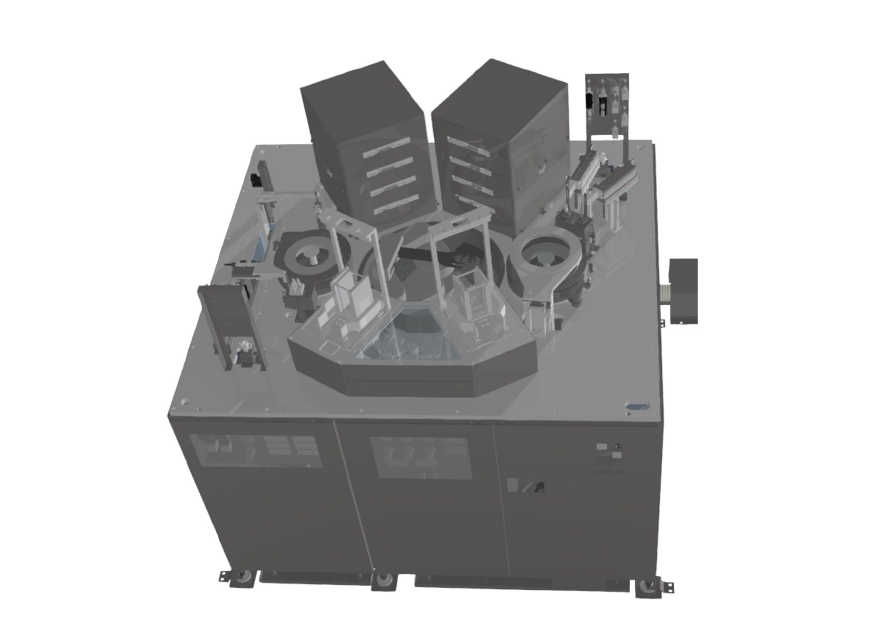

Coaters/developers02Standard models

Type: Standard

Amount processed: 500/day

Equipment size: Medium

Robots: 1

- Standard type capable of processing 500 wafers per day Unitified cluster system for optimum specifications

-

This automatic conveyer for mass production is equipped with a double hand wafer conveyer robot. Up to four stages of process units can be installed, and the multistage type baking unit can be expanded to up to five stages. Capable of processing over 500 wafers per day and suitable for a range of processes, whether using high or low viscosity solution.

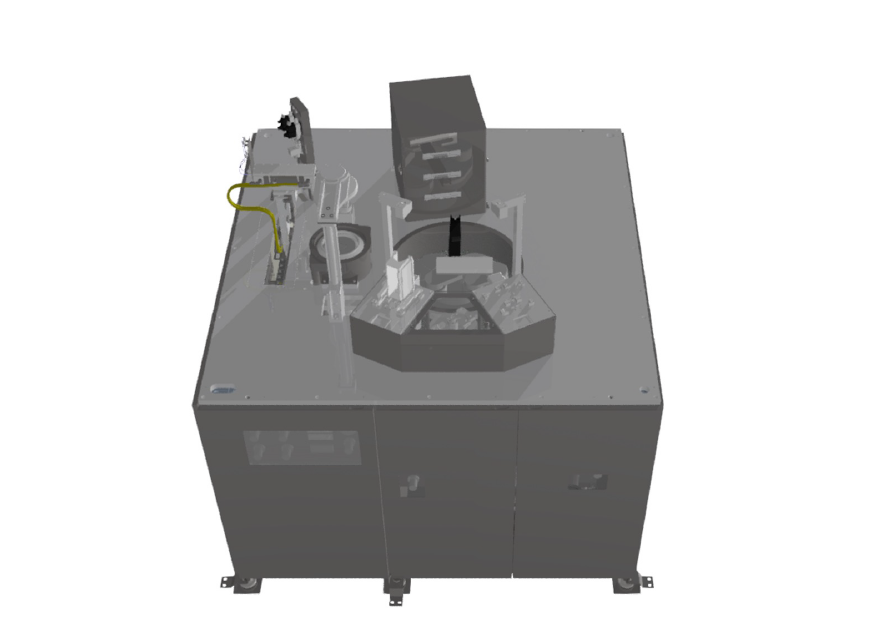

Coaters/developers03Research and development (R&D): R&D models

Type: Research and development

Amount processed: 100/day

Equipment size: Small

Robots: None

- Compact equipment perfect for research and development

Customization for special materials and processes available Minimal wafer processing equipment designed for research and development; full customization options available. -

In addition to equipment with wafer conveyance robots, we also offer manual machinery for small batch processing. We offer equipment to suit your research objectives, capable of handling high viscosity solutions of over 10000cp or those cured at temperatures over 400°C.