TECHNOLOGIESASAP’s technological strength

Technology you can trust Defectiveness rate brought down from 4% to 1%

Fully customize your semiconductor production equipment to suit your factory size and needs and maximize efficiency

ASAP produces and markets photolithography processing (coating, exposure, development) equipment for use in semiconductor production.

Suitable for silicon semiconductors or compound semiconductors, we focus on micromachining for equipment capable of producing semiconductors with a substrate size of 2-8 inches in diameter, or with irregular substrate size.

All of our equipment enables you to easily adjust the size in inches.

At ASAP, we handle everything from settings to production in house.

With our full customization options, we provide low-cost, compact equipment with optimal specifications.

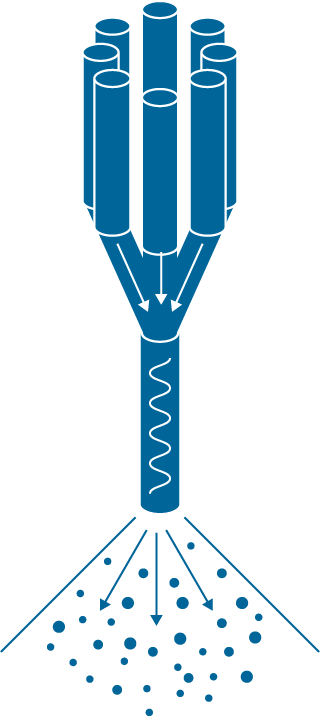

ASAP’s technological strength 101Lift-off equipment the best microcavitation high-pressure jets

Microcavitation high-pressure cleaning removes metal burrs with lift-off

- Microcavitation

-

- Cavitation creates microbubbles.

- Lift-off equipment uses high-pressure jets

-

- Jets with our specially developed nozzles have a maximum pressure of 20MPa

- Capable of damage-free lift-off on sheets as thick as seven micrometers as well as fine patterns of just 100 nanometers

- Removes organic film residue and metal burrs

Before processing

Before processing During processing

During processing After processing

After processing

- Microcavitation high-pressure cleaningRemoves organic film residue and metal burrs

Completely eliminates resist

Completely eliminates resist - Other companies’ dip methodRemoves organic film residue and metal burrs

Metal burrs, resist organic film residue

Metal burrs, resist organic film residue

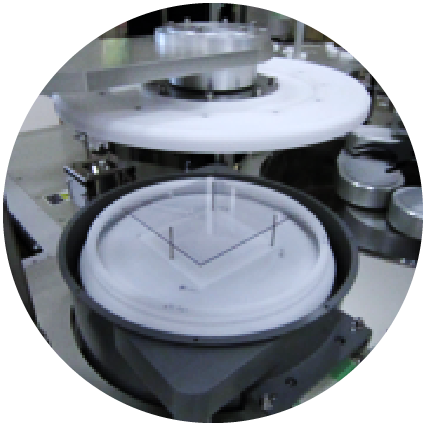

ASAP’s technological strength 202A wealth of experience with and research on thick film coating

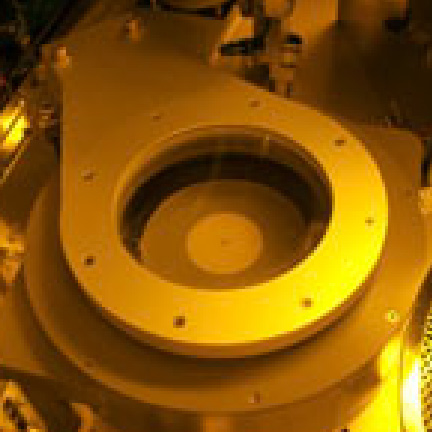

- Our patented (no. 3821468) rotating cap coater

-

- Coats square substrates fully and evenly.

- High viscosity solution (up to 14000cP) enables low-resist coating.

- Proven and potential applications

-

- SAW filters,

- Photomasks, LEDs,

Sub-mounts for power devices, - Rotary encoders,

Crystal devices, - optical devices (LED, LD)

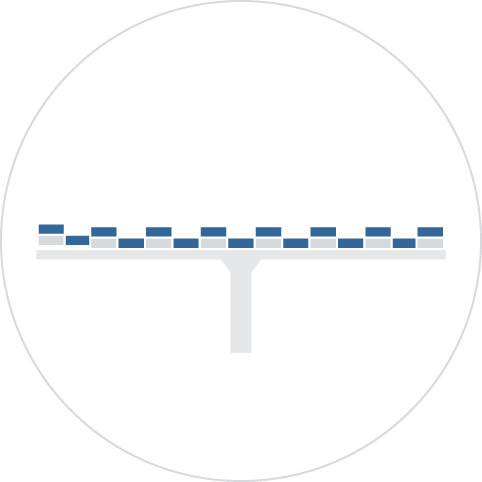

- ASAP’s three types of coater caps

-

- 1Open type

-

- For standard positive type resist coating

Well suited to thin film, low viscosity resist coating - Compatible viscosity (cp): Up to 200

- Distribution (±%): 0.3-1.0

- Features

- Evenly distributes low viscosity resist coating

- For standard positive type resist coating

- 2Closed type

-

- For negative type resist coating (cobwebbing prevention)

Also well suited to positive R thick film and high viscosity coating - Compatible viscosity (cp): Up to 2000

- Distribution (±%): 0.5-2.0

- Features

- Evenly distributes negative resits and high viscosity resist

- For negative type resist coating (cobwebbing prevention)

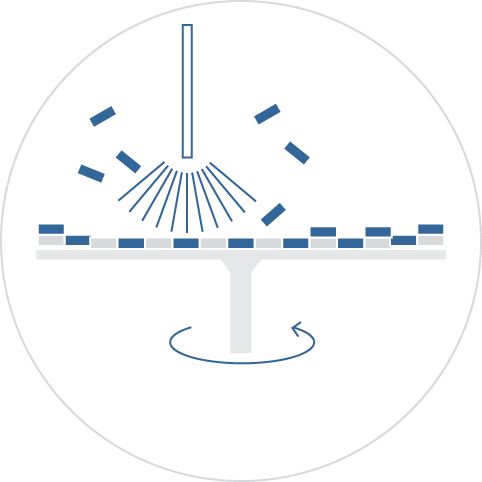

- 3Rotating cap type

-

- Well suited to coating square, rectangular, and uneven substrates, high viscosity, or material minimization

- Compatible viscosity (cp): Up to 10000

- Distribution (±%): 1.0-3.0

- Features

- Evenly distributes extremely high viscosity resist and polyimide

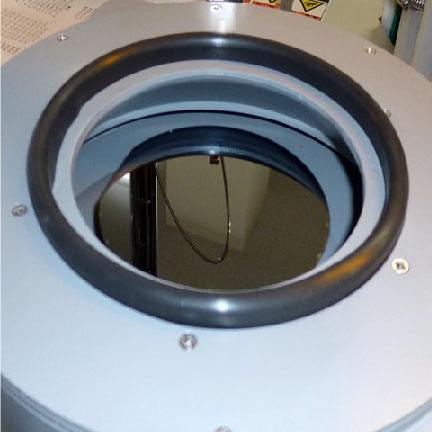

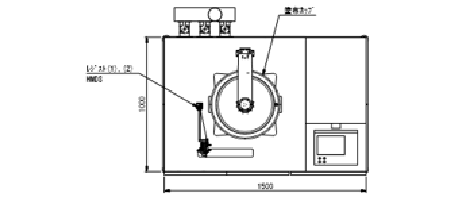

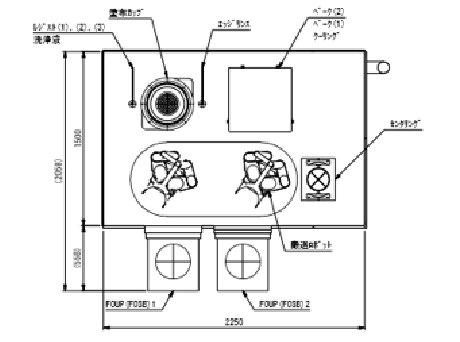

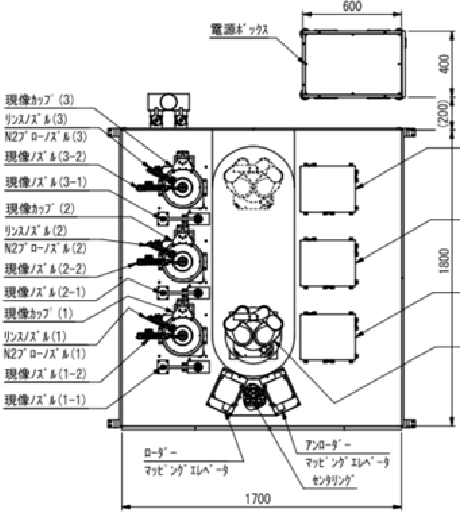

ASAP’s technological strength 303 Customization

- Equipment custom built to fit the user’s needs

Example: Number of processing caps and liquid nozzles - Fully customizable designs made to suit the customer’s production scale, objectives, and design layout

- Special substrates and custom products ready in no time

- Capable of use with multiple wafer sizes at once!

Example: 2&4 inches, 4&6 inches, 6&8 inches, etc

- ASAP offers everything from manual machinery for research and development use to mass production equipment

We offer customization to suit your needs and objectives at a reasonable price. -

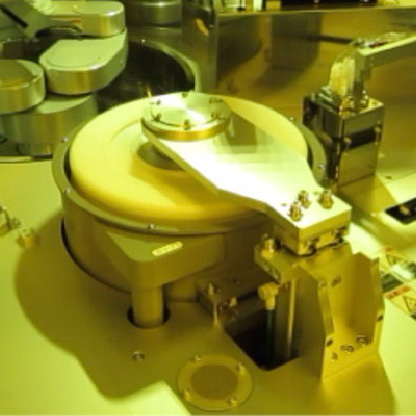

<Manual machinery>

<Manual machinery> <Φ300 FOUP compatible equipment>

<Φ300 FOUP compatible equipment> <3-cap mass production equipment>

<3-cap mass production equipment>