Mask aligner

var Eviry=Eviry||{};Eviry.Player||(Eviry.Player={});Eviry.Player.embedkey="EK1jZ2aNve3Yy7o5P1P_hQDNzBBFjbFBzJenMBtS_6BzTYk6f44Zavtohb8pLGIDOVXlbb7tt2pvfBQzhuSfwtmufA0YqytuMSCSvX3ENNvFmM.";C to C is auto batch scale exposure mask alignment equipment.

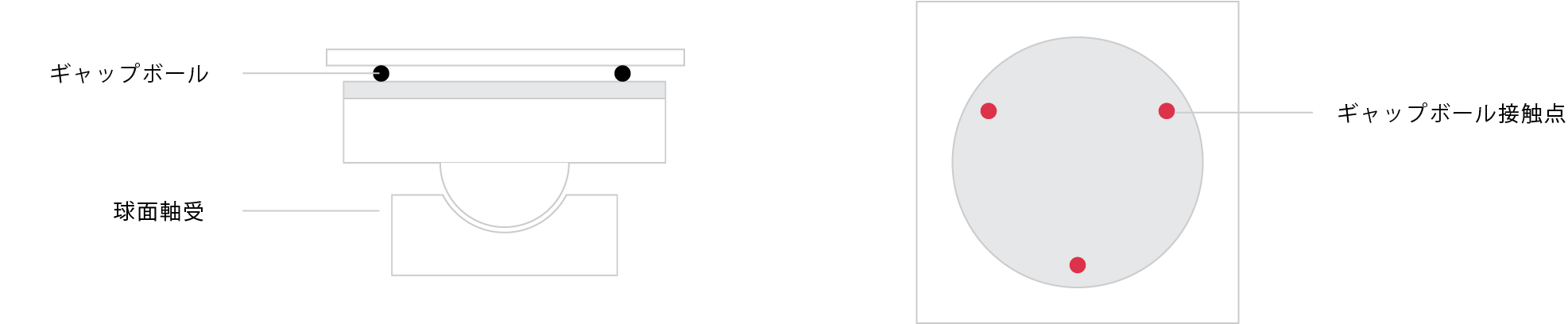

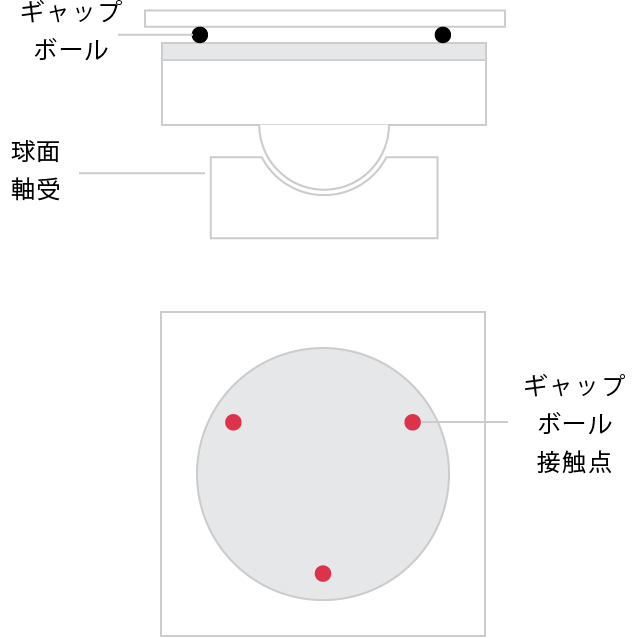

It conducts gap management without any contact with the mask.

Of course, it is also capable of soft and hard contact!

Compact and low cost auto alignment is now possible.

Three features

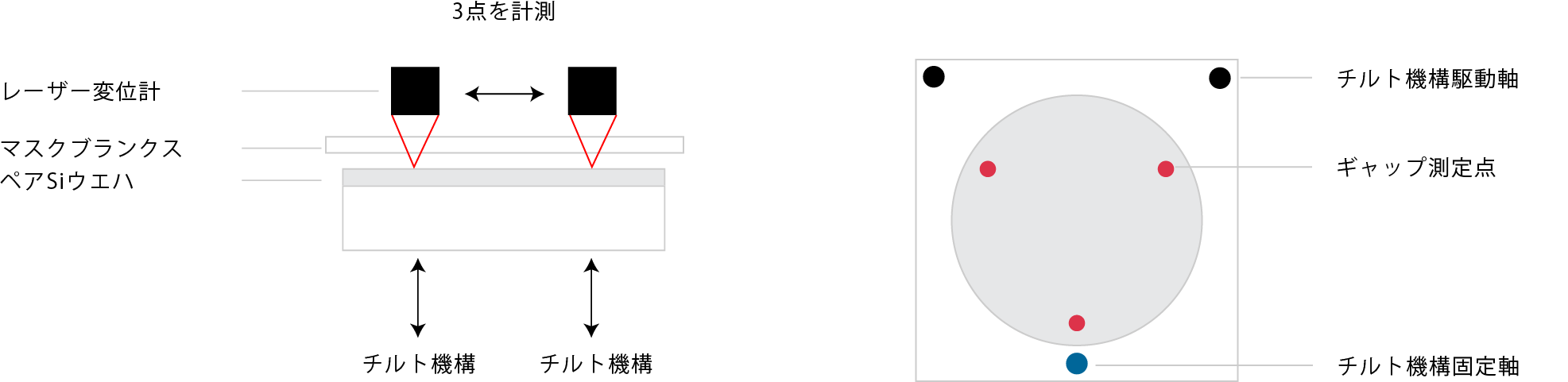

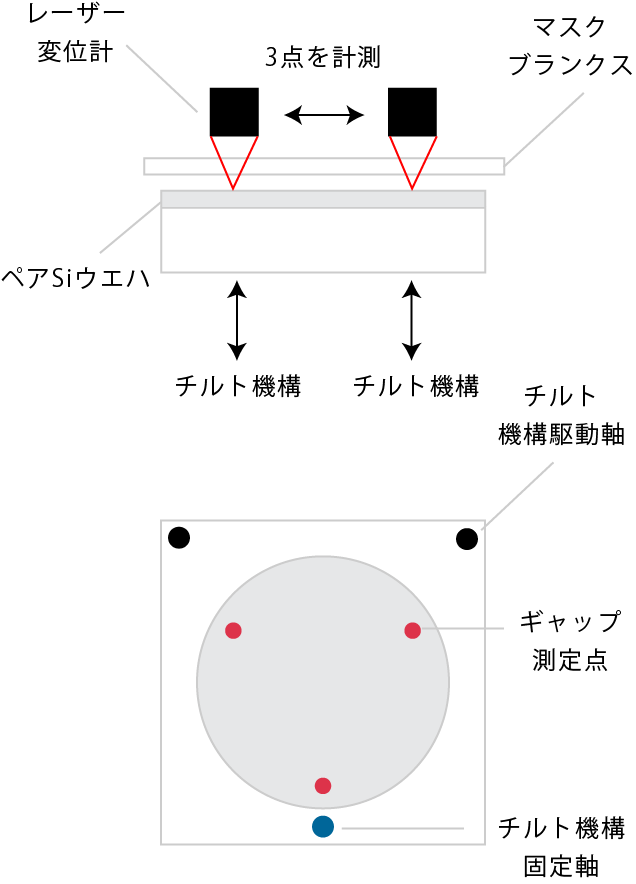

- 1Parallelism correction

and exposure without any contactHigh accuracy laser displacement

meter handles parallelism correction,

and performs exposure without contact,

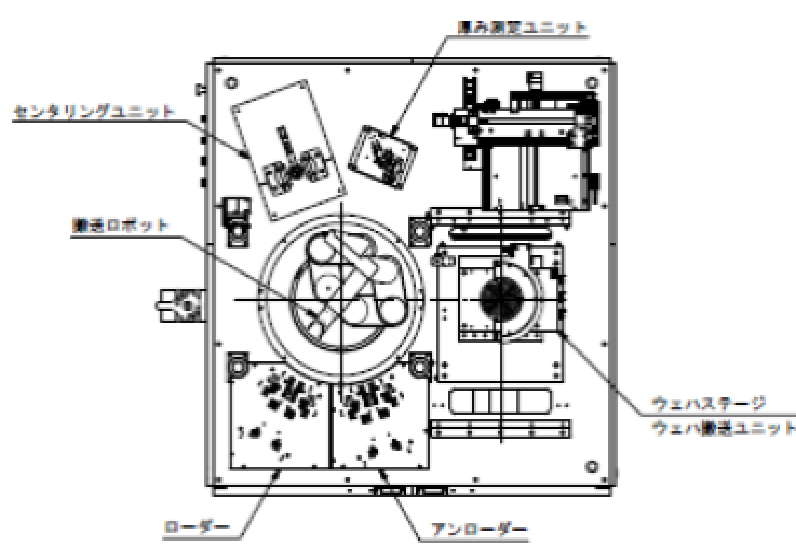

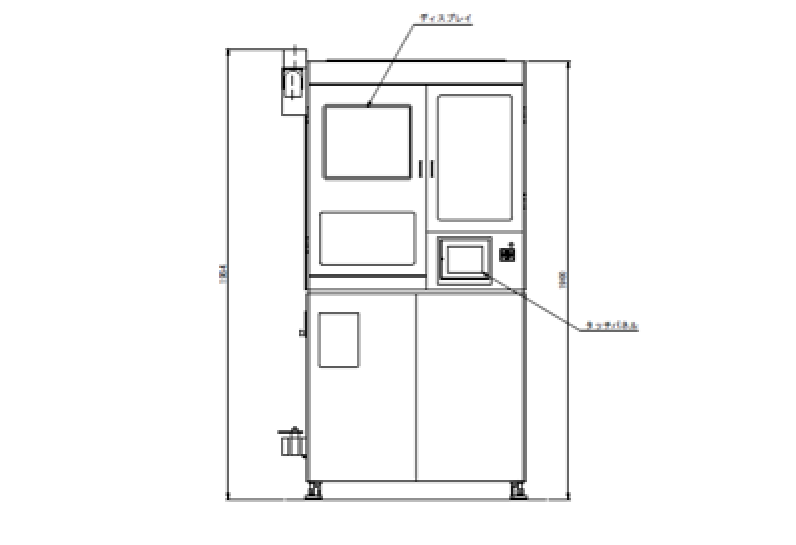

so the mask is not damaged! - 2Space saving and

low maintenanceWith small robots

space saving, at just 1m x 1m in size.

What’s more, the center robot

layout makes

maintenance a breeze. - 3Auto alignmentImage processing by FAST,

a brand you can trust

for high accuracy auto alignment!

Comparison with old design

- Old design

-

Three points of damage to the gap ball!

- ASAP design

-

Gap ball control with no contact whatsoever,allows for parallelism control

Contactless design prevents damage to mask and wafers!

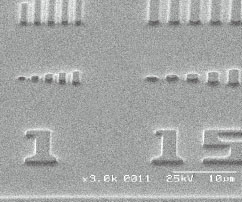

- Exposure capacity

-

Conditions

- Substrate:Si (HMDS treatment)

- Film Thinckness:0.8um (OFPR-800LB)

- Prebake:90℃/90s

- Developer:NMD-3 (2.38%)

- RInse:DI water/20s

(Image is for illustration purposes only. Results may vary depending on conditions.)

(Image is for illustration purposes only. Results may vary depending on conditions.)

- Primary specifications

-

- Wafer size:2"-6"

- Mask size: 3"-7"

- Exposure proximity (gap adjustment range 0-999um)

- Illuminance uniformity(irradiation diameter 165mm)

- Exposure control integral light meter or timer setting

- Image processing system2 million pixel CCD + image processing engine by FAST

- Wafer stage UVW3 axis stage+ Z axis + tilt 2 axis format

- Basic features

-

- Resolution for20umGAP: Under 5um

- Alliant accuracy within ±1um

- Throughput robotconveyance type: 120wph

Mechanical conveyance type: 150wph